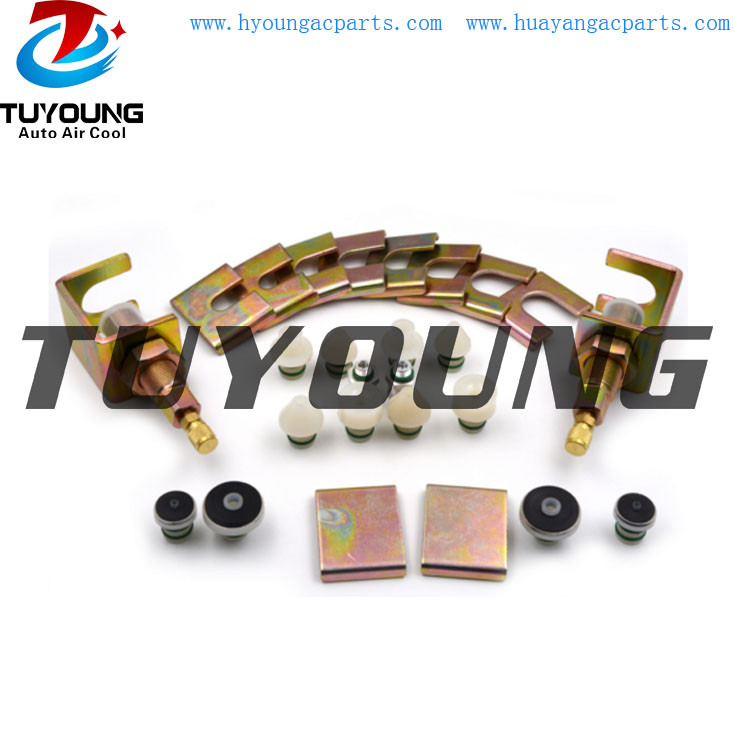

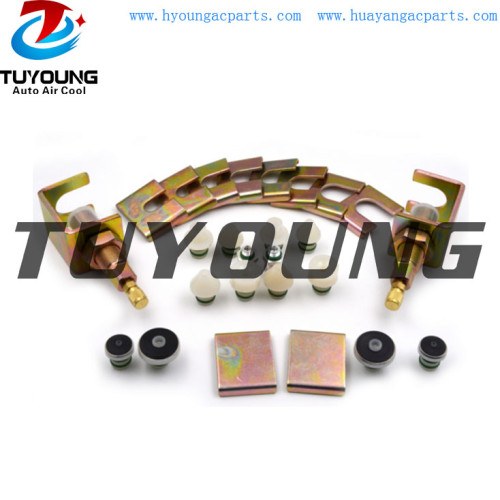

Universal vehicle AC Conditioner Repair tool box , A/C Leak Testing Detector Tool / Flush Fitting Adapter Kit

- Model

- HY-TL70

Item specifics

- brand name

- HYoung

- fit

- Universal

- type

- A/C Leak Testing Detector Tool / Flush Fitting Adapter Kit

- quality

- high

Review

Description

Universal vehicle A/C Leak Testing Detector Tool / Flush Fitting Adapter Kit

Tool Box contain:

2 x Clamp Assembly

2 x Support Plate (1/2" OD tube)

2 x Support Plate (5/8" OD tube)

2 x Support Plate (3/4" OD tube)

2 x Support Plate (7/8" OD tube)

2 x Support Plate (No slot)

Description:

These instructions are intended as guidelines for general operation of the Universal Flush Fitting Kit. Follow the vehicle manufacturer's instructions for flushing A/C systems.

The clamp assemblies and support plates included in this kit can be installed on most A/C line or tube ends for attachment of the flushing apparatus being used.

The support plates are slotted to allow for different size tubes or line nuts to be supported against the lower end of the sealing clamp. The chamfered area on the support plates allow the flared end of the tubes to sit level. This way the sealing cone can be seated without slipping or damaging the end of the tube.

Seating of the sealing cone into the fittings or tube ends does not require the use of wrenches or other tools. Sealing cones damaged by tools must be replaced.

Installation of the Sealing Cone:

1. After selecting the correct support plate to fit the tube or line fitting, tighten the clamp screw until the cone is seated tightly against the end of the tube or line fitting on the A/C component.

2. While holding the clamp screw by hand, rotate the forcing nut an additional 1/8 to 1/4 turn. This provides a leak-tight seal for the flushing operation.

To remove the clamp assembly, hold the clamp screw and back off the forcing nut to free up the sealing cone without damaging the end of the cone.

When using adapters on a tube or fitting that is too small for the sealing cone to enter, replace the coneshaped seal with the concave seal.

To replace the sealing cone, hold the forcing nut and back out the clamp screw until the cone is pulled out the end of the clamp screw. Insert the desired sealing cone into the end of the clamp screw, and tighten the screw until the cone bottoms in the screw, using the non-slotted support plate against the end of the cone.